Search This Supplers Products:Plastic machinery, injection mouldInjection molding machineBlow molding machineHDPE extrusion machine

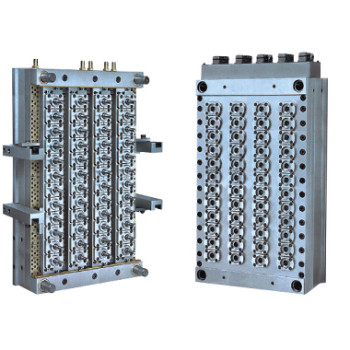

Preform Mould With Hot Runner Valve Gate

- group name

- PET Preform Mould

- Min Order

- 1 piece

- brand name

- Senio

- Nearest port for product export

- SHANGHAI, NIGNGBO

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- T/T, Westem Union, Cash

- update time

- Wed, 24 Oct 2018 10:18:58 GMT

Paramtents

Product name Preform Mould With Hot Runner Valve Gate

Packging & Delivery

-

Min Order1 piece

Briefing

Detailed

PET Preform and Hot Runner Moulds

Details: We offer

– Preform moulds and hot runner systems up to 96 cavities

– Components for preform moulds and hot runner systems manufactured by Husky, MHT, Sipa, Otto Hoffstetter, SIG, Nissei ASB, Aoki, etc.

– Blow moulds for all types of re-heat stretch blow moulding machines

– Preform and container development services including prototyping

– Turnkey solutions for preform or PET container manufacturing

Characteristics (preform moulds and hot runner systems):

– Components are manufactured to extremely high levels of precision

– Premium quality steel and heat treatment used

– Hardness of all stack and hot runner components range from 50 to 70 Rockwell

– Balanced runner system with perfectly matching channels and no dead spots

– Excellent thermal isolation between mould (8 to 20 Degree C) and hot runner elements (280 to 290 Degree C)

– Premium quality heaters and thermocouples used in the hot runner system

– Generously sized quick coupling water connectors and cooling channels

– Water is distributed to mould stacks within the mould base – only 2 inlets and outlets for the mould

– Moulds are compatible with hot runners manufactured by Husky (or MHT according to customer preference) and vice-versa

– Hot runner components are interchangeable with standard Husky and MHT PET hot runner systems